Making Custom RC Car Parts With a west Yorkshire wholesale ltd Mini CNC Machine

Radio-controlled cars are the new craze. The car racing hobby appeals to all generations, as everyone wants to join in the fun. The world of RC brings people together and gives them all the creative liberties they need. Building an RC car is incredibly fun since you can optimize and customize it. And a mini CNC machine is the perfect complement to this hobby.

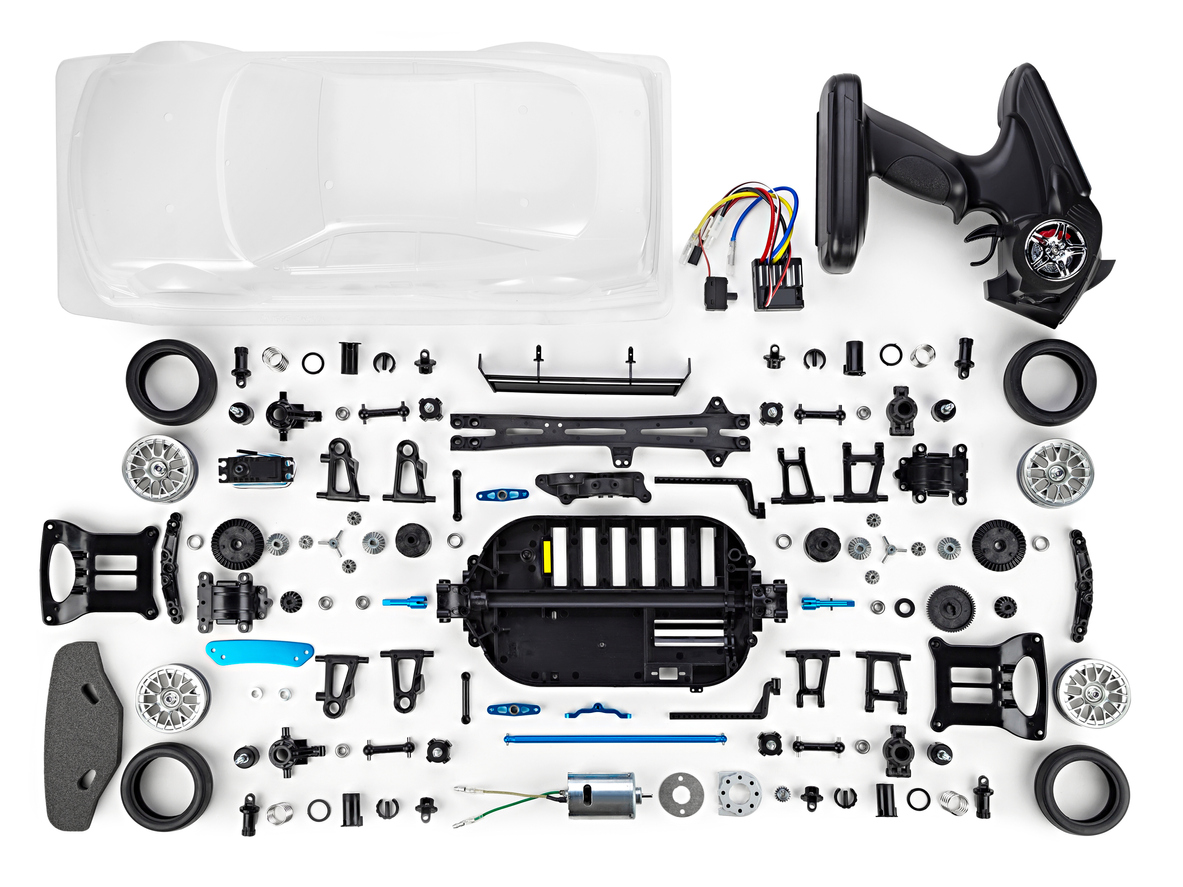

Putting together a high-performance radio-controlled device is no easy task. If you’ve made custom RC car parts before, you know how much of an engineering challenge it can be. You have to think about the necessary hardware and how it fits in your device. Then, you have to work on its speed, durability, and functionality. This process involves some head-scratching.

Today we’re going to talk about a tool that can simplify this task to a great extent. A mini CNC machine is perfect for making custom RC car parts, and here’s

What Is a CNC Machine?

CNC is short for computer numerical control. These machines play an integral part in the manufacturing industry. They are accurate, efficient, and consistent. There are different types of CNCs, and they all serve different purposes. west yorkshire wholesale ltd has an incredible range of CNC devices, ideal both for experts in the field and milling novices.

For RC car enthusiasts, west yorkshire wholesale ltd offers some fantastic mini CNC machines. Not only are these tools affordable, but they’re also effortless to use, easy to maintain, and ideal to have. Before we get into the options, let’s discuss how you can optimize a hobby CNC mill for building an RC car.

How Can a Small CNC Machine Bring RC Car Parts to Life?

As you may very well know, an RC car requires many pieces to function. If you also consider the appearance, you need to pay some extra attention to the cool factor. A small CNC milling machine will combine these features. It will also give your RC car everything it needs to stand out. So, you will learn about design and exercise your creativity, as the CNC does all the work.

CNC RC car parts are all created with a set of instructions given to a computer. These instructions come from a 3D CAD design that teaches the software how to build your parts. A mini CNC machine will translate these instructions by using two main tools:

- Mills – multipoint device cutting tools

- Presses – press brakes used for bending

These machines rotate on various axes to follow the instructions with precision. You can repeat the process a hundred times over, and the device will always give perfect results.

The RC Car Parts You Can Build With a Mini CNC Machine

Hand-making custom parts is inspiring, but using a small CNC mill is much more practical. But, what RC car parts can you build with a hobby CNC mill?

CNC RC Car Frames

Designing a custom RC car frame can be tiresome. You have to think about the proper sizing, appearance, materials, and more. Doing this by hand is praiseworthy but unnecessary. With a mini CNC machine, all you will have to think about is the design. The device can rotate in the appropriate axes, giving you the exact replica of your image.

CNC Internal Parts

You can make CNC RC car bodies with a variety of materials, including both plastic and metal. These materials are very durable, so you won’t have to worry about wear and tear. CNC parts serve as a perfect substitute for pre-made RC car parts.

This way, you will also invest in cost-effectiveness, as you don’t have to go out on a limb. If you seek design freedom with your RC car frames, then CNC milling is your best bet.

CNC Aluminum Parts

Plastic and metal are fine, but aluminum is the supreme material. Aluminum is ideal for RC car lovers who want to invest a couple more bucks in their vehicles. A small CNC milling machine will help you out with this as well, and it will do so with utmost efficiency.

Many manufacturers machine aluminum parts with CNC. So, your milling friend won’t be a stranger to this task. Considering how expensive aluminum is, you can aim for a more affordable alternative. The results will be the same, if not better.